Our Sustainability Initiatives

All our ophthalmic instruments are single-use and fully recyclable

Sustainability Initiatives

The healthcare industry accounts for 4.4% to 5.2% of global GHG emissions – and with cataract rates rising, that number is not going down any soon.

Preserving the planet for future generations is a big priority for us. This is why we are proud to pioneer the development of a comprehensive reuse cycle, enabling the stainless steel used in our instruments to have a second life in non-medical devices.

Since the inception of HASA OPTIX, our founders have remained resolute in their commitment to utilising exclusively stainless steel in the manufacturing of our instruments, driven by its exceptional recyclability properties. This deliberate choice not only sets us apart from our competitors in the single-use market, but also serves as a testament to our unwavering dedication to achieving our corporate sustainability initiatives and objectives.

To address the complexities of establishing a recycling system, we have adopted a step-by-step approach through the #HASARecycle programme.

Today, we proudly take a step forward and start building our closed-loop cycle, giving a second life to the stainless steel our instruments are made of.

Our Green Partners

We are proud partners to various companies with the same mission and vision.

Renewi and Greencycl are important partners joining us in our #HASARecycle circular economy project. As our trusted waste management partner, Renewi plays a crucial role in organising, collecting, and transporting our instruments from hospitals and clinics. With their expertise and commitment to environmentally beneficial practices, Renewi facilitates a safe and efficient collection of used instruments.

Greencycl, our trusted partner specialising in recycling solutions, handles the critical task of processing the collected instruments. This collaboration has bloomed into a successful initial project in the Netherlands, where we have already collected over 600kg of used instruments for recycling.

This closed-loop recycling scheme has helped us to become shortlisted as one of Belgium’s Most Sustainable Companies at the Trends Impact Awards in the Circular Economy category.

#HASARecycle is only one of our corporate sustainability initiatives. We have also launched a collaboration with CLIMACT in order to assess our environmental performance, take accountability for our operations, and create a comprehensive action plan to reduce our carbon footprint.

Lastly, we are B Corp certified, because sustainability is not just about the environment – it’s about all who use it. This certification gives us the opportunity to showcase our commitment to governance transparency, worker rights, and giving back to our community and customers. View our profile here.

The Recycling Process

As a recyclable ophthalmology instruments company, our global objective is to extend our support to hospitals, clinics, and surgical centres that demonstrate an interest in recycling their surgical instruments and, on a broader scale, managing their operating room waste responsibly. We aim to be a reliable partner in enabling these healthcare facilities to embrace sustainable practices and contribute to a greener future.

In collaboration with client hospitals, local waste management companies, and our distributors, we are actively developing and maintaining localised recycling testing projects in several countries. By introducing designated “green bins” in operating rooms, we demonstrate our ability to collect and recycle instruments, effectively recycling and reusing the raw materials in other products.

We aspire to foster collaboration with companies, associations, and individuals sharing our vision of effectively managing and reducing the waste generated by ophthalmic operating rooms worldwide. Together, we can work towards sustainable solutions and improve waste management practices in the field of ophthalmic surgery.

Involvement of Medical Teams

While our recycling programme was built with user experience in mind, there are still some steps medical staff need to make to ensure the successful recycling of our instruments.

It is highly encouraged for medical staff to sort out the various elements of our packaging: the pouch/blister, the instrument, and the silicone tip protector if relevant. Please find a more detailed guide below, or visit our ‘Quality & Standards’ page to learn more.

Waste Disposal Procedure

#HASARecycle is our step toward creating a closed-loop recycling programme. We place special ‘green’ bins in hospitals and clinics upon request. There, they get filled up by medical staff, and, once full, are picked up by our waste collection partner to be decontaminated and transported to a recycling facility. Afterwards, they get either crushed into stainless steel powder or melted down, and sold back into the market to be made into other products.

For more detailed instructions, please read the guide to the right.

Adapting to Climate Change

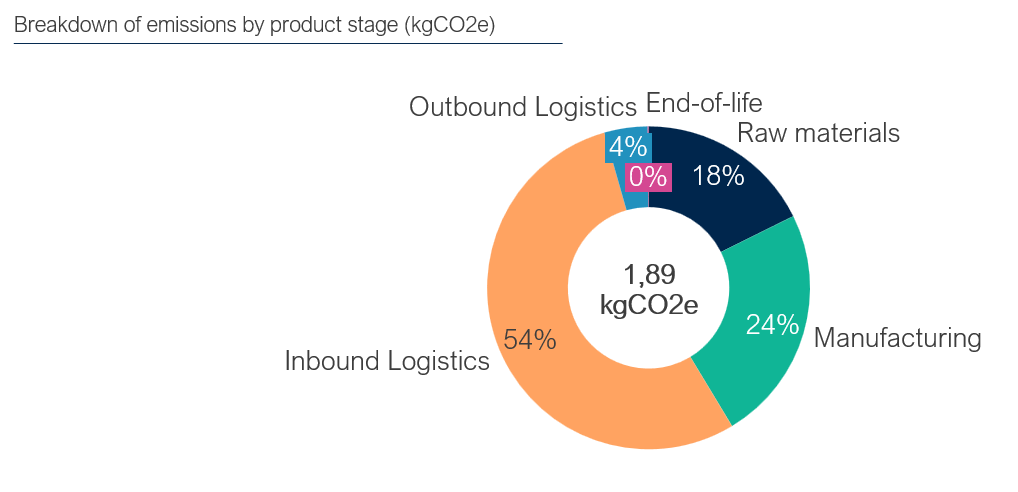

With rising cataract surgery rates and the worsening of our climate, it’s difficult to ignore the effects single-use instruments can have on the environment. That is why we have decided to partner with CLIMACT to assess and survey our carbon footprint and create a comprehensive action plan to reduce it. You can view the report here.

Our research with CLIMACT encompasses all aspects of our logistics and supply chain, starting from the raw material, and all the way to their disposal. Using these insights, we are able to create a plan targeting actions most offensive to the environment.

Not only are our instruments recyclable, but so is our packaging. Made from LDPE film, our Tyvek® pouches are meant to be disposed of in plastic recycling bins.

Interested in our products?

Would you like to learn more on how we help simplify the organisation of the operating room, control cost per surgery and increase quality of care?

We’re always here to help, and we would love to hear from you!